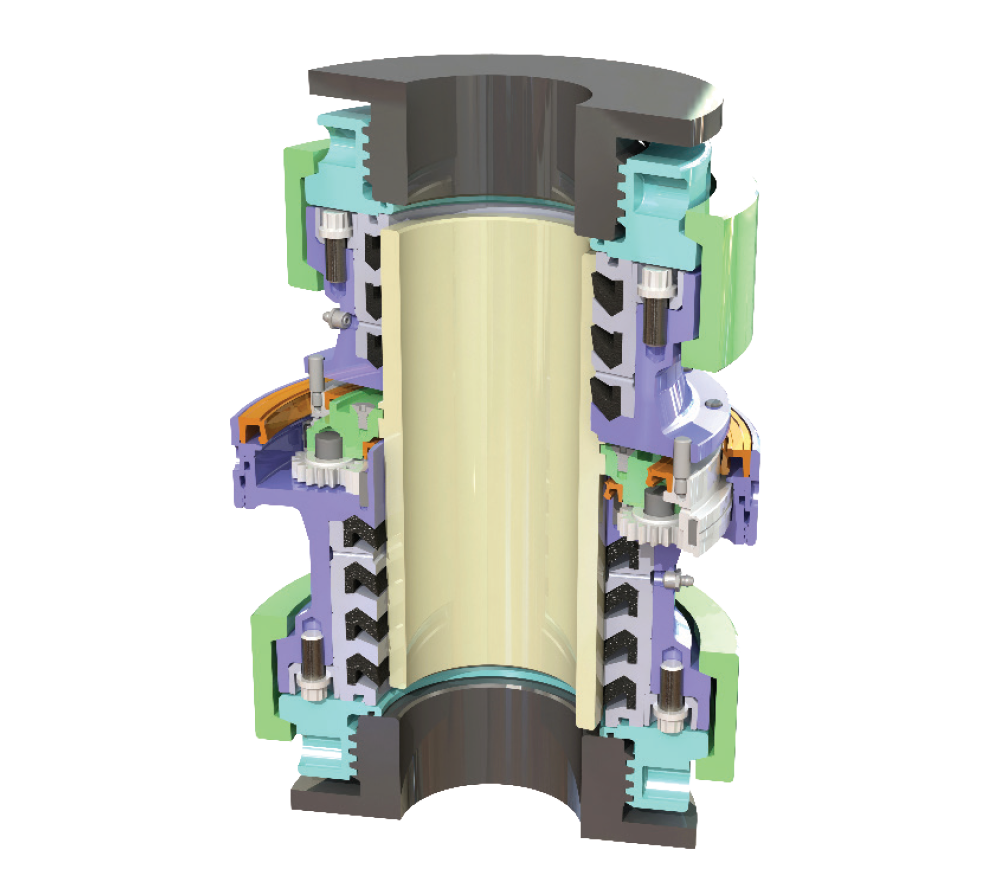

Sur-Drive™ Epicyclic Swivel

Rpm on packing seals reduced

Self-aligning

Hammerless installation

Self-aligning

Hammerless installation

TDS11 Hi-TORK Upgrade

Increases motor horsepower and available torque

JM 300 (I-BOP) Top Drive Valve

Z TORQUE

Reduced drillstring vibration

Up to 50% faster

Friction reduction software

Up to 50% faster

Friction reduction software

Spare Parts

Extensive inventory stocked in all drilling regions

GLM Catwalk

Automation for safety

Power and precision

Custom packages

Power and precision

Custom packages

Friction Reduction Enhanced Drilling

Friction reduction

Reduced drilling time

Compatible with OEM brands

Reduced drilling time

Compatible with OEM brands