EST 2003

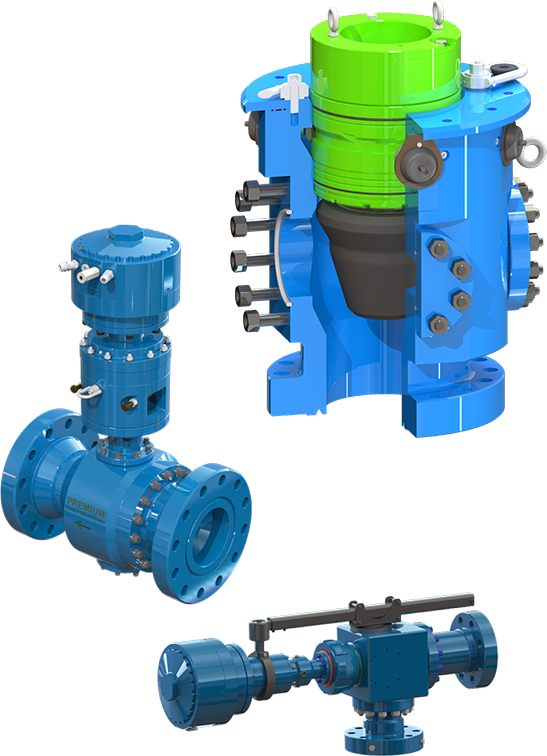

Premium Oilfield Technologies was started in 2003 with the initial goal of providing mud pump expendables directly to the drilling rigs in West and South Texas through consignment boxes and direct sales relationships with the rigs. The idea was that by fostering close, face-to-face working relationships with tool-pushers and rig-managers, we would be dealing directly with the users that cared about the quality and performance of our products. And, having that direct feedback on our products, we could design, build, and test our new products, and make the best tools in the industry.

Fast forward 21 years later, and Premium is now the #1 manufacturer and provider of mud pump systems and expendables in the US land drilling market. Every day we sell to more than 80% of the operating rigs in the US shale plays, where some of the harshest and most challenging drilling takes place. However, our footprint is no longer limited to the US. We now have operations and sales in Canada, Mexico, Dubai, Saudi Arabia, Kuwait and India.